Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:www.dlyouyan.com

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

Plastic blown film machine, as a key equipment for plastic product production, plays an important role in packaging, agriculture, industry and other fields. With the advancement of technology and changes in market demand, plastic film blowing machines continue to develop and innovate in areas such as high efficiency, energy saving, intelligence, environmental protection, multifunctionality, and high-precision control. In the future, plastic blown film machines will continue to drive the development of the plastic film industry, providing high-quality and high-performance plastic film products for various fields.

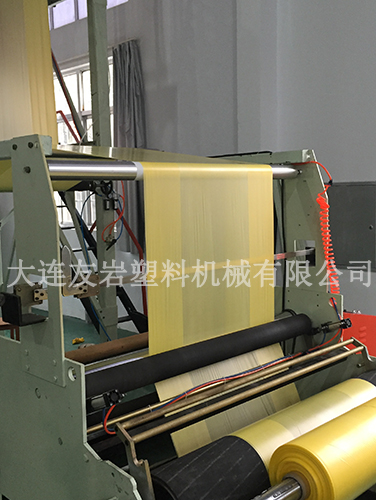

The extruder is the core component of a plastic blown film machine, responsible for heating, plasticizing, and extruding plastic raw materials. Extruders typically consist of screws, barrels, heating devices, and drive systems. Mold is a component formed from plastic film blank, and its design directly affects the thickness uniformity and quality of the film. Common types of molds include circular die heads, spiral die heads, and so on.

What are the common problems in the use of Dalian plastic blown film machine?

1、 Uneven film thickness

reason:

Uneven temperature distribution in the mold head, with local temperatures being too high or too low, resulting in inconsistent melt flow rates.

The unstable screw speed affects the uniformity of material extrusion.

The inflation ratio is too large or too small, exceeding the equipment process range, resulting in uneven lateral thickness of the film.

The airflow distribution of the cooling air ring is uneven, and local cooling is too fast or too slow.

2、 Bubbles or crystal dots appear on the film

reason:

Raw materials that are damp or contain impurities release gas at high temperatures to form bubbles, while impurities form crystal dots.

The extrusion temperature is too high, and the material decomposes into gas due to overheating; Or the temperature may be too low, resulting in insufficient plasticization of the material.

The screw and the barrel are worn, and the gap is too large, resulting in material retention and degradation.

3、 Poor transparency of thin film

reason:

The cooling effect is insufficient, and the crystallinity of the film is too high (especially for polyethylene materials), which affects the light transmittance.

The raw material formula is unreasonable, such as excessive fillers or uneven dispersion.

The flow channel inside the mold is not smooth, and material retention leads to degradation, or the pulling speed is too fast, resulting in uneven stretching orientation of the film.

4、 Insufficient tensile strength of the film

reason:

The inflation ratio and traction ratio do not match, and the better stretching orientation effect has not been achieved.

Improper selection of raw materials, such as excessively high resin melt flow rate (MFR) and low molecular weight.

The extrusion temperature is too high, leading to the breakage of polymer molecular chains and a decrease in mechanical properties.

5、 Irregular or adhesive film winding

reason:

The speed of the traction roller and the winding roller is not synchronized, and the tension control is unstable.

Excessive or insufficient winding pressure, or uneven surface of the winding roller.

Insufficient cooling of the film and high surface temperature can cause adhesion during winding, especially in high humidity environments.

Excessive accumulation of static electricity in thin films can lead to dust adsorption or mutual adhesion, requiring the use of a static eliminator.

Plastic film is an important material in the packaging industry, widely used in food packaging, daily necessities packaging, industrial packaging, etc. Common packaging films include polyethylene (PE) film, polypropylene (PP) film, etc. Agricultural film is mainly used for greenhouse and plastic film covering, and has functions such as insulation, moisture retention, and insect prevention. Common agricultural films include polyethylene (PE) film, ethylene vinyl acetate copolymer (EVA) film, etc.

The working principle of plastic film blowing machine is relatively simple, but it involves the collaborative work of multiple links. The basic process is as follows: raw material preparation: plastic particles or powders (such as polyethylene PE, polypropylene PP, etc.) are fed into the extruder through a hopper. Heating and plasticization: In the extruder, plastic raw materials gradually melt through heating and the rotation of the screw, forming a uniform molten plastic. Extrusion molding: Molten plastic is extruded through a mold (also known as a die head) to form a tubular plastic film blank. Blow molding: At the exit of the mold, compressed air is blown into the interior of the film blank to expand it into thin film bubbles. Cooling and shaping: The expanded film bubble is cooled by a cooling device (such as an air ring) and gradually shaped into a film. Traction and winding: The cooled film is pulled by a traction roller and finally wound into a coil, completing the entire production process.