Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:www.dlyouyan.com

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

Plastic blown film machine, as an important plastic processing equipment, plays an irreplaceable role in the production of plastic products. With the continuous advancement of technology and the increasing market demand, the technical level and production efficiency of plastic film blowing machines are also constantly improving, contributing to the development and progress of the plastic packaging industry.

The development trend of plastic film blowing machines is mainly reflected in the continuous improvement of automation, production efficiency, and increasingly strict requirements for environmental protection and energy conservation. With the advancement of technology, plastic film blowing machines have also made new developments in intelligence and digitization, making the production process more efficient and convenient.

Detailed explanation of the usage method of Dalian plastic blown film machine

preparation. Before using the plastic film blowing machine, it is necessary to check whether the equipment is intact and whether there are any foreign objects blocking it. Check if the power, water, and gas sources are connected properly. Then install the equipment correctly according to the equipment manual, ensuring that the equipment is in a stable working state.

Power on preheating. Turn on the power switch of the plastic film blowing machine, adjust the temperature regulator to the appropriate temperature, and power on for preheating. Set the appropriate extrusion speed and temperature according to production needs to ensure that the machine can operate normally.

Feeding and extrusion. Put the pre prepared plastic particles into the feeding port of the plastic film blowing machine, start the extruder, heat and melt the plastic particles, and then extrude them through the extruder to form a thin film like raw material.

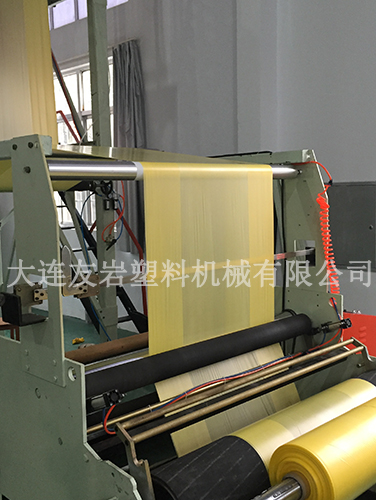

Blow film. Stretch, cool, and blow the extruded film using the blown film head of the blown film machine to form the desired film thickness and width. Adjust the pressure and speed of the blown film machine to ensure stable quality of the film.

Roll up. After the blown film process, the thin film product is rolled up by a winding machine. According to the requirements, the film can be cut into suitable sizes for easy packaging and transportation.

Clean up. After using the plastic film blowing machine, clean the equipment in a timely manner to ensure its cleanliness and hygiene, and extend its service life.

The plastic blown film machine has the advantages of high production efficiency, easy operation, and low cost, and can meet the needs of films of different sizes and thicknesses. According to the different types of plastics used, plastic blowing machines can produce various types of plastic films such as polyethylene film, polypropylene film, polyvinyl chloride film, etc.

The working principle of a plastic blown film machine is to heat and melt plastic particles, extrude them through an extruder, and then stretch them through a film forming mechanism to form a thin film of a certain thickness, which is then cooled by a cooling device to solidify and form. Throughout the entire production process, it is necessary to control parameters such as extrusion temperature, film-forming speed, and thickness to ensure stable film quality.