Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:www.dlyouyan.com

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

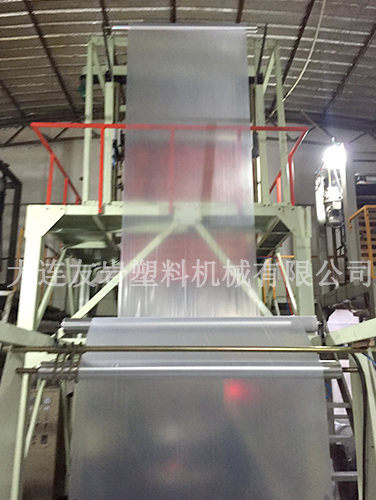

Three-tier co-extrusion blown film machine, multi-layer co-extrusion blown film machine is divided into several, such as layer co-extrusion blown film machine, three-tier co-extrusion blown film machine, five layers co-extrusion blown film machine seven layers co-extrusion blown film machine is belong to this kind of products such as: five layers co-extrusion blown film line, mainly is suitable for the HDPE, MHDPE, LDPE, LLDPE, MLLDPE, PA, EVOH has gas barrier properties of resin, such as the production of thin film is mainly used for packaging, high-grade food bag, vacuum bag, liquid packaging bags and other packaging materials, incense, fresh, anti-corrosion, airtight, extend the shelf life of the packing.

After the film bubble is stabilized, the thickness and width of the film are measured to see if it meets the required standards. If the thickness is thin, vice versa. The width is controlled by air pump.

Over the past 20 years of reform and opening up, China's plastic packaging industry has been steadily developing at a high speed, has developed from a decentralized industry at the early stage into an independent, complete product categories of modern industrial system. According to conjecture, to 2005 the market year demand of field of our country plastic packaging material will reach 5.5 million tons, average annual demand growth rate is 1O%, in plastic product industry growth rate is fast, it is the sunrise industry that has broad development prospect.

Will dry polyethylene particles added to the hopper, depend on the weight of the particles themselves from the hopper into the screw, when the aggregate after contact with thread oblique edge rotating slant edge face plastic produce and inclined faces the vertical edges of thrust, plastic particles move, goes on in the process, because the plastic and screw, plastic and barrel friction between the friction and collision between particles, but also gradually melt due to external heating cylinder. The molten plastic is filtered by the machine head to remove impurities from the die head die mouth, cooled by the air ring, blown by the herringbone plate, traction roll, roll the finished film into a cylinder.

The three-layer co-extruding and blowing thin production line adopts advanced technologies such as new efficient and low-energy extruding unit, IBC membrane bubble internal cooling system, ±360° horizontal upper traction rotation system, photoelectric automatic deviation correction device, automatic winding and film tension control, computer screen automatic control system and so on. Compared with similar equipment, it has the advantages of higher output, good plasticization, low energy consumption and simple operation, which completely solves the problems such as film flounce and winding size.