Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:www.dlyouyan.com

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

The film can be made of those materials

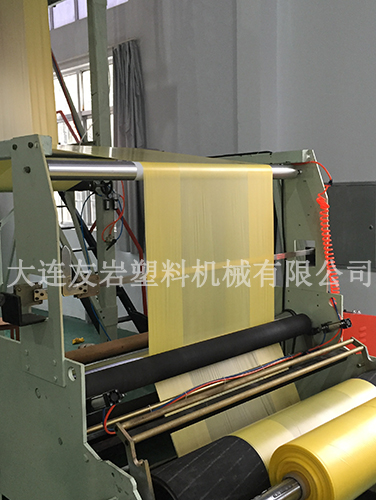

Dalian's three-layer coextruder is composed of extruder, machine head, die head, cooling device, stabilizer, human word board, traction roll, coiling device etc. Extruder extruder mainly consists of screw, machine, hopper, reducer and drive motor. By means of belt drive reducer, decelerator drives the screw to rotate in the cylinder. Screw with special structure, that is, in a screw a mixing device, equipped with in a special work on plastic hold a centering around the screw shaft installed in the reducer to force 7310 or 7614 bearing with screw, barrel of feeding mouth design, according to raw material properties to successfully enter the screw groove was sent away, to ensure the quality of transmission capacity and stable extrusion.

The polyester thin film is therefore polyethylene terephthalate, which is the material of the polyethylene terephthalate, which is obtained by extruding the legal system into thick film, and then it is made of thin film material. It is a colorless, transparent, light film, excellent mechanical properties, high rigidity, hardness and toughness, durability, resistance to friction, high docile low temperature resistance, chemical resistance, oil resistance, good air tightness and sweet, is one of the permeability resistance of composite film base material. However, the cost of polyester film is higher, usually 12mm thick, which is commonly used as the outer material of cooking packaging and is better in printing.

Cast polypropylene film is acceptance of flow process production of polypropylene film, and can be divided into ordinary CPP and CPP two level cooking, excellent transparency, thickness of symmetry, and the performance of the horizontal symmetry, usually used as the lining of the composite film material. Ordinary CPP film thickness is usually between 25 and 50 microns, and after the OPP composite has good transparency, bright appearance, feel is strong, gift bags are usually accepted this kind of material. The film also has a good thermal seal. Cooking class CPP film thickness is usually between 60 to 80 microns, which can withstand temperatures up to 121 ℃, 30 min cooking, oil resistance, good air tightness and heat sealing strength is high, usually the meat cooking level inner packing are to accept the CPP film.

Dragon film is a very solid film, good transparency, and has good light, high tensile strength, tensile strength, but also has good heat resistance, cold resistance, oil resistance and organic solvent resistance, abrasion resistance, durable thorn is excellent, and softer than force, oxygen resistance is excellent, but poorly insulated to water vapor, moisture absorption and moisture permeability is bigger, poor heat sealing property, suitable for packing rigid objects, for example greasy food, meat, Fried food, vacuum packing food, cooking food, etc.