Dalian Youyan Plastic Machinery Co., Ltd.

Couplet: Feng Manager

Phone/fax:086-0411-86260347

Hand:18624289888

13604263838

Mail box:21272059@qq.com

Network access:www.dlyouyan.com

Address: Chinese Lushunkou District of Dalian City, the three streams town (take Tuchengzi Dalian to Lushun Road westbound vehicle airport about 200 meters in front of about 100 meters)

The use of the film blowing unit and the matters needing attention

Film blowing machine is heated to melt the plastic particles and then blown film. There are a variety of film blowing machine, PE, POF, PVC and so on. With a blown film blowing machine the new particle is the new material, color, clean, good stretch the bag.

Pay attention to matters of film blowing machine installation

Three layer co extrusion film blowing machine installation should pay attention to adjust the center of extruder head center line and the traction roller to maintain horizontal and vertical, and shall not deviate from the skew. When receiving the volume, the increase of the diameter of the receiving coil, please pay attention to the coordination of the traction speed and the rolling speed. After the host is open, pay close attention to the operation of the host, timely adjustment, correction, electrical instruments, controllers to ensure its normal operation. Main gear box, traction gear box should always come on, the replacement of gear oil, the new machine use the 10 days to replace the new gear oil, to ensure the normal operation of the rotating parts, filling the attention, prevent jammed and overheat damage, should also check the connecting parts of the fastening, prevent the bolt loosening. The compressed air in the bubble tube should be kept in proper amount, because the compressed air leakage will be brought out in the process of traction.

Correct use method

Check the temperature controlled condition, heating appliances in good condition, pay attention to adjust the heating temperature in the index range in time.

Check the traction speed control film thickness.

3 to observe and adjust the film thickness uniformity, folding size standard.

The inspection of the air storage cylinder pressure is not too high, but due to standby pressure.

The check and control the ratio of raw materials mixed evenly.

The inspection of raw materials has no impurities, especially should check with the iron magnet.

But check the gear box and the air compressor cylinder lubricating oil lubrication.

The regular inspection of the operating temperature of the motor and mechanical transmission.

Note before the use of film blowing machine

1) make operation personnel familiar with blowing machine operation standard.

2) heating extruder body, head, die head, control the temperature of each point within the index.

3) such as suspension and drive, the heating temperature of the index range is constant for 10-30 minutes, such as parking within half an hour drive, is not constant.

2, boot preparation

1) through the water, electricity, gas, and check whether the normal, such as abnormal situation in a timely manner to find equipment maintenance personnel.

2) the first extruder fourth, five and 1, 2, rotary die head 3, 4 district heating to 120 DEG C, keeping temperature for 2 hours, and then rose to the process temperature, at the same time, 1, 2, 3 extrusion temperature zone temperature to process the heat for 1.5 hours.

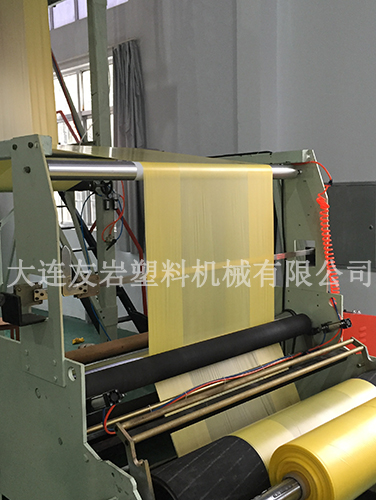

Film blowing machine